- How to Locate Air Leaks on the pressure side of the pump to find the source of the air leak: use soapy water to spray the connections and components. If you see bubbles forming, that indicates a leak. Tighten loose connections or replace damaged components to fix the issue.

- How to Locate Air Leaks on the vacuum side of the pump: Unique places we have leaks have been on flush valves, these are often bolted together via a flange and allow for bleach lines to be flushed with water simply by turning a handle. The seals that that allow these valves to work will wear and allow air to enter the system on the vacuum side. Tighten these up periodically when you notice the handle starts to move too freely. (see: banjo 3 way flush valve image)

Common 12v Softwash Equipment Problems and How to Fix Them

Softwash equipment is a popular and effective method for cleaning various surfaces, including buildings, roofs, and concrete. However, like any equipment, softwash systems can experience problems that require troubleshooting and repair. In this blog post, we will provide an overview of common softwash equipment problems and offer solutions to fix them.

Basic 12v Softwash Equipment Checks

Before diving into more complex solutions, it's important to perform some basic checks to ensure that your softwash system is in good working order. Here are some steps you can take:Check for Loose Connections: Make sure that all connections are tight and secure. Loose connections can cause leaks and reduce the efficiency of the system.

- Inspect Hoses and Nozzles: Check for any damage or wear on the hoses and nozzles. Replace any damaged components along with the tightness of jubilee clips.

- Check the pump electrical connections: Make sure the terminals on the pump are free from rust and are fully connected.

- Its can be easy to miss: Check their is charge on the leisure battery that powers the 12V pump… And most importantly it is turned on!

How To Find Leaks On 12v Softwash Systems

Air leaks are a common problem in Softwash equipment and can cause the system to lose pressure and efficiency. Here's how to locate and fix air leaks:

- Causes of Air Leaks: Air leaks can be caused by several factors, including loose connections, worn-out o-rings, and damaged components.

- Symptoms of Air Leaks: If you notice a drop in pressure or hear hissing sounds, these may be indications of air leaks in the system.

How To Prevent Air Leaks On 12v Softwash System

The best way to deal with air leaks is to prevent them from happening in the first place. Here are some steps you can take to prevent air leaks and ensure the best performance out of your equipment.

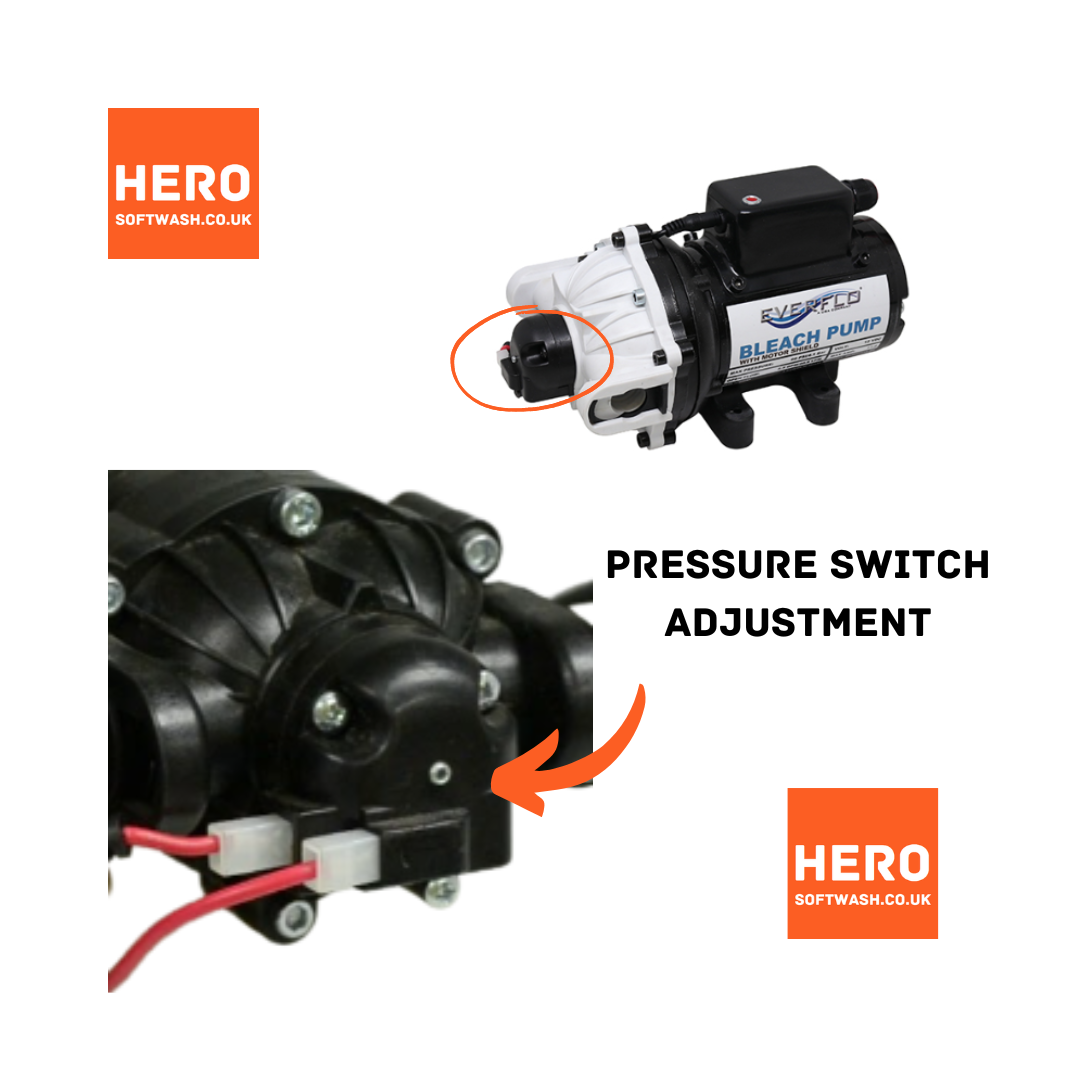

Pressure Switch Adjustment For A 12v Softwash Pump That Surges On and Off

If your 12v softwash pump is surging on and off, it may be due to a faulty pressure switch or a non calibrated pump. Here's how to adjust the pressure switch to get the best performance:

How to Know When to Replace Your 12v Softwash Pump?

Softwash pumps CAN last for several years with proper maintenance, but eventually, they may need to be replaced depending on usage. Here's how to tell when it's time to replace your pump:

- Signs of a Failing Pump: If you notice a decrease in pressure or flow rate, strange noises, or leaks, these may be signs of a failing pump.

- Factors to Consider When Deciding to Replace the Pump: What is the cost if your pump fails when your out on a job. The age of the pump, and the frequency of repairs if your pump is beginning to cause your problems.

Conclusion

In conclusion, regular maintenance and troubleshooting are essential for keeping your softwash equipment in good working order.

By performing basic checks and taking the steps to prevent air leaks, you can keep your softwash system running throughout the year trouble free. Carrying spares and tools on your work vehicles is a real saving grace, and a big consideration every softwash professional should consider when running their business.

If you’ve found this article useful, don’t forget to check out our other articles on our blog. View some of our cleaning videos and tips on our youtube channel @herosoftwash

Oh Yeah... And we make awesome softwash equipment in the UK!