What is softwashing and how do you soft wash?

What is softwashing?

Softwashing is a process used to clean external surfaces at low pressure, which is where the term softwash comes from.

Not every material is suited for low-pressure softwash but it's important to know what it is and how effective it can be for cleaning surfaces, especially with the added use of a pressure washer.

By combining three ingredients:

- Water

- Surfactant

- Sodium hypochlorite

The main cleaning agent is diluted high-strength sodium hypochlorite typically measured at 12-15%. When used with a surfactant which can be described similarly to soap. The combination of these ingredients allows for brilliant cleaning results. Understanding just this part of what makes up soft washing is just the surface.

Surfactants and the main ingredient sodium hypochlorite which is commonly known as bleach or in the industry as SH or Hypo is very hazardous to the environment, people, and the environment when used irresponsibly without proper protective equipment and knowledge.

Softwashing is a very safe and effective way of cleaning homes when carried out by a professional company

What can you clean using soft washing?

Exterior hard surfaces can be cleaned using a soft washing process from Roofs, driveways, natural stone, fencing, decking, and UPVC. Each surface has a different tolerance to soft washing. We must remember that sodium hypochlorite is the base ingredient in every softwash solution... Bleach. So the strength of your solution should be considered for the surface that you are cleaning. If you were to compare the two materials such as a wooden fence compared to a natural stone. The texture of the materials is completely different from fibrous wood compared to a tough porous natural stone. The stone material can handle a stronger softwash solution verse a wooden fence yet both can be cleaned using a softwash cleaning process.

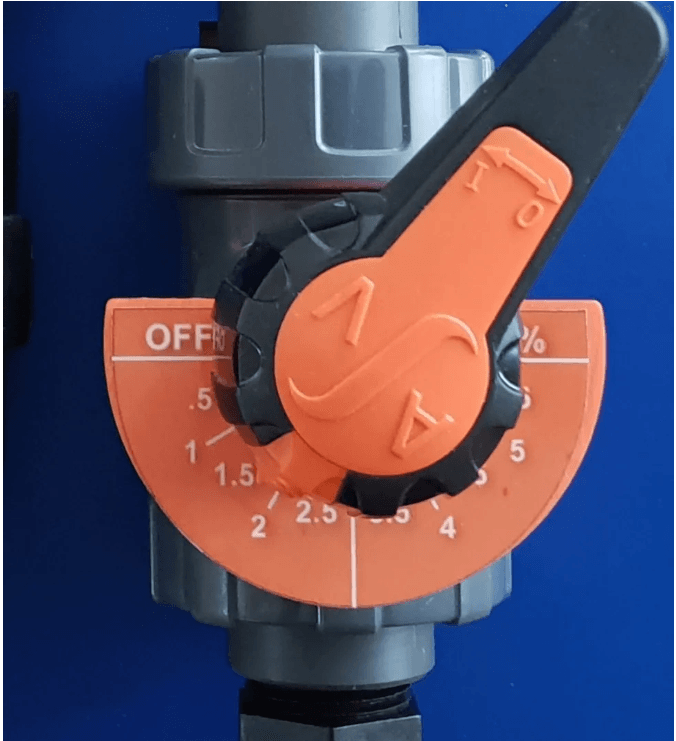

What stength softwash solution do I need?

Below is a handy quick guide for the strength of softwash solution you would need for surfaces suitable for cleaning but don't be fooled! It is always best to test your softwash solution on a small discrete area before proceeding to clean the whole area. If you incorrectly identify a material there would be an adverse reaction with the ingredients in your softwash solution.

A new addition to homes in recent years is the use of organic materials within different building products. For example, with some modern paints, organic pigments can react with bleach and leave patchy paintwork. This is just one of the many situations that can cause unwanted stress for the softwash professional and worst the homeowner. Be sure to test your softwash mixture on a discrete part of the home before proceeding.

| Softwash % | Material |

|---|---|

| 1% | Timber decking, Ordinary paint, Light staining |

| 2% | Ashphalt drive, Render, Stucco, Vinyl Siding, Durable paint, Screen enclosure, Fencing, Cedar shakes, Dryvit, Steel cladding, |

| 3% | Stained UPVC, Pool decks, Shingle roofs, Glazed tile roof |

| 4% | Brick work, Indian sandstone, Flagstones, Pavers, Blocked driveway, Concrete, Slabs |

How to mix Softwash chemicals

You can measure your softwash solutions by hand by carefully measuring your volumes of concentrated cleaning products into a tank. When doing so you must wear all the correct personal protective equipment such as gloves, specialized mask, eye protection, and suitable clothing. Many accidents occur when mixing a softwash solution. Many operators choose to buy pre-made solutions from providers online. The issue with this is a pre-mixed solution comes at a cost. Most commercial softwash and pressure washing businesses choose to make their softwash recipes.

The safest and most effective way to mix your softwash chemicals is using a Softwash Mixing System. This eliminates the need for you to mix your chemicals by hand minimizing contact with concentrated cleaning solutions. Check out our range of softwash mixing systems that save you time and money compared to manual mixing or buying pre-made solutions.

View our range of softwash mixing valves and systems below